Mezzanines, or mezzanine platforms, are a popular type of industrial furniture; they are essentially un-walled, raised platforms. Note that the mezzanine card is not a type of industrial mezzanine. Mezzanine cards are instead a particular type of printed circuit board (PCB) assembly. Read More…

As a manufacturer of mezzanines, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

Since 1982, Equipment Roundup Manufacturing has manufactured products such as mezzanines. Our mezzanine structures include mezzanine systems, mezzanine floors, industrial mezzanines & plant mezzanines.

Are you looking for a ready-to-use mezzanine? Our team can handle the design and install so that when we're done, it is ready for you to go to work. When you choose PWI we drastically increase your workspace, in many cases customers create new work or additional storage space. Our steel mezzanines are an affordable alternative to new construction and ensures you are getting the most out of your...

ResinDek® flooring is the solution for mezzanines, work platforms, pick module flooring, and equipment storage. ResinDek® panels have been installed in distribution centers, manufacturing plants, cold storage facilities and many other applications because of its strength, durability, versatility, and variety.

Since 1995, Panel Built has been a leading manufacturer and distributor of modular buildings. Our booths and partitions are available in a wide range of materials including solid phenolic, metal powder-coated, and high-pressure laminate. Panel Built also has an extensive list of washroom accessories including, but not limited to waste receptacles, combo towel waste unites, and grab bars. If our...

Since 1985, Donobrog has been providing low cost easy mezzanines, inplant offices, pick modules, pallet racking and shelving systems…. “Turn Key – New and Used””. Sales, Engineering, Fabrication and Installation. Our labor also can tear down, move, re-assemble and repair existing storage systems. Contact us to discuss your facility improvements.

More Mezzanine Manufacturers

Mezzanine Applications

Mostly, customers use mezzanines to make room for workers and working equipment, to store unused materials, and to increase work space efficiency. This is why some people call them “work platforms.” In addition, mezzanine platforms have some applications unrelated to storage. They can, for example, provide a surface or ceiling for offices; an office could be built above or below a mezzanine.

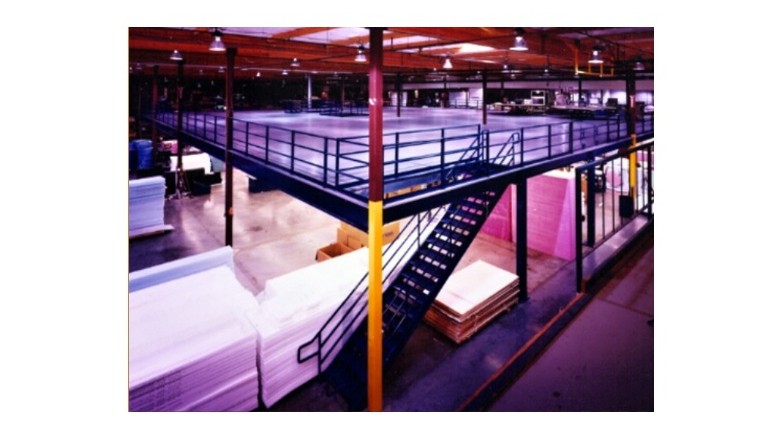

Mezzanines are an additional floor that is constructed between the main floor and the ceiling. Hence, it is not included when counting the total number of floors in a structure. Mezzanines maximize the vertical area while doubling the usable space and is applicable to all types of building.

Some create easy transportation between mezzanine floors and building ends; they can even transport guests and visitors. They also provide auditorium seating. Mezzanines are a common tool used by service companies, distribution centers, and suppliers alike.

Mezzanines are meant to provide facilities for the occupants residing in high-rise buildings. They are usually used as office space for comfortability while taking up minimal space, catwalks to not disturb the flow of production when there is a need for mobility, and in theaters that serve as the balcony’s front rows.

One main feature of a mezzanine to differentiate it from other structural setups is that it occupies 25% of the basic floor’s area. This alone makes it as such, whether it looks like a balcony, a loft, or just a confined space.

Being an intermediate floor between the ceiling and the main floor, a mezzanine is excluded from the maximum floor space. It must have a minimum of one-third of the floor space below it. They are constructed with the purpose of increasing storage space or added to increase market value. Lastly, they often have a minimum height above and below the main floor of 2 meters.

History of Mezzanines

Mezzanine has two different French meanings, derived from the French cognate, mezzanine, and the alternative French term entrensol. First, the French mezzanine is derived from the Latin mezzanino, or mezzano for short. Mezzanino means middle. Next, entresol is a French term, sometimes used in English, that refers to either a mezzanine or a room created by partition.

No matter which term you look at, the overarching impression that we get from the etymology of “mezzanine” is that people first thought of them as structures that divided vertical spaces or horizontal spaces across their middle.

People first used mezzanine platforms in the theater, where they assisted in seating by service as the lowest balcony. The French also used mezzanines (entresols) in architecture, particularly in the apartments at Versailles.

Mezzanine applications broadened in a number of ways during the Industrial Revolution. Not only were they useful in warehouses and storage facilities, but they were also popular in department stores, which were a byproduct of Industrialization. (Industrialization lead to the mass production of products, which eventually lead the advent of department stores.)

Today, manufacturers can provide for their customers a wide range of mezzanine products at an affordable price. The possibilities with mezzanine structures are much wider than they used to be. For example, since the 1990s, engineers have had access to an increased range of high quality composite wood products. Also, manufacturers can create mezzanine structures that reflect the environment requirements, space requirements, and strength requirements of their customers much better than they were ever able to in the past. Mezzanines are an essential feature of the industrial world, and we can be sure that in the coming years, engineers will find ways to make them even more useful and durable.

Types of Mezzanines

Mezzanines come in a great variety of configurations. Some mezzanines, including many free-standing mezzanines, are prefabricated for flexible, modular assembly, often for the sake of short term use. Still others are nothing more than a petite platform, used for tool storage.

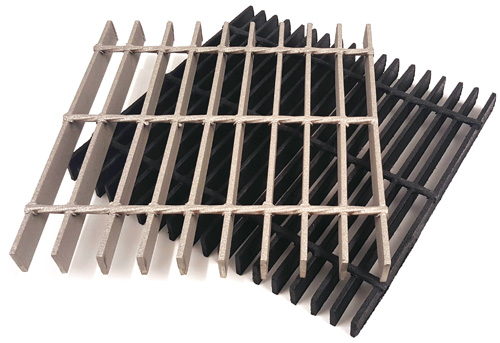

Steel mezzanine floors are the most common flooring material for industrial and office buildings. There are two main types of steel mezzanine floors, closed or solid steel decking and open grid steel decking.

Closed steel decking includes a checker plate or “Vastrap” deck that are just plain steel sheets. It has a raised pattern on the top side of the steel sheet, making it a non-slip surface where one can walk. These steel sheets can be welded together to create an impervious steel floor ideal for companies that demand a high level of cleanliness.

Open grid mezzanines come in two varieties, the open grid steel deck and the steel grating deck. The first one uses a bolt together system consisting of perforated steel plates bent up into a c-type channel arranged in a staggered manner. The latter type is a very strong steel manufactured deck made up of a welded flat bar and round bar sections that create a square grid platform.

Benefits:

- Moisture Resistant: Steel does not rust even when frequently exposed to wet conditions, specifically stainless steel.

- Portability: Due to its lightweight feature, steel is often used in companies that do not require permanent mezzanine installations and require mobile mezzanines. For example, lease spaces will need to transfer their equipment when they reach the end of their contract. Having a portable mezzanine will ease the turnover, or the company can resell them if deemed unnecessary.

- Quick Installation: Steel mezzanines are fabricated off-site. They are usually pre-ordered, therefore saving them time and labor that would have been spent on-site for their construction.

- Design Flexibility: Steel’s versatility allows curves and other creative features to be included in the mezzanine design.

Common mezzanine types include structural mezzanines, freestanding mezzanines, storage mezzanines, metal mezzanines, in-plant mezzanines, plant mezzanines, prefabricated mezzanines, modular mezzanines, office mezzanines, warehouse mezzanines, and perimeter mezzanines.

Structural mezzanines receive partial or full support from a permanent building. This is because they are usually built into a building at the same time that building is built. Manufacturers build structural mezzanines with the goal that they free up surface area for machinery and store surplus products and equipment.

Freestanding mezzanines, usually made from structural steel, stand independent of support. In contrast to structural mezzanines, freestanding mezzanines are usually added after the fact and perform fewer demanding tasks. This type of mezzanine is quite popular in the market nowadays. They are not part of the main structure and are considered fixtures that can be easily reconfigured, whether to be assembled or disassembled when there is a change of plans or needs. They are ideal for holding platforms for heavy types of machinery or equipment, businesses that require repositioning or transferring of mezzanines, and maximizing floor area.

Storage mezzanines are used in factories and warehouses. There, they provide additional storage space for equipment or goods. They may be structural, or they may be freestanding. Regardless, manufacturers usually make them from steel or stainless steel.

Metal mezzanines are actually raised platforms; they have applications in stores, factories, warehouses, and in other industrial or commercial contexts, such as office spaces and storage spaces.

In-plant mezzanines are any mezzanine that is constructed inside a plant or building. Manufacturers usually ship in-plant mezzanines to their destination unassembled, and allow customers to put them together upon arrival.

Plant mezzanines simply serve as transitional floors in industrial plants.

Prefabricated mezzanines are mezzanine systems that manufacturers design and partially assemble before end-user full assembly. You may also hear prefabricated mezzanines referred to as “pre-engineered mezzanines.”

Modular mezzanines are a type of prefabricated mezzanine that comes in standard size offerings. Modular mezzanines are generally less expensive and quicker to receive and install, but they are usually limited to a lighter PSF capability.

Office mezzanines are simply raised platforms under or above which users can curate office space.

Warehouse mezzanines are raised platforms that customers use to create extra ground floor or mezzanine floor space in warehouses.

Perimeter mezzanines are added to large buildings to create an observation deck where overseers can keep an eye on floor operations. They also provide an easy means of transportation from one end of a building to another.

Shelving and Rack Supported Mezzanines are a very practical type of mezzanine since it involves integrating another shelving system into existing storage. Instead of structural legs, they are supported by rack uprights. They’re ideal for storage and a catwalks, allowing easy retrieval of products, and maximizing vertical space.

Catwalks function as a walkway or an aisle that allows navigation within the entire cube of the building. It acts as the access for a worker to store and retrieve products from shelves, racks, spans, or pallets. Less popularly known as a viewing platform or maintenance platform. They’re ideal for expanding floor space, open-air designs, avoiding expenses for additional storage, minimizing moving expenses, and reducing the dead load on the floor.

Full Mats are a combination of both freestanding and catwalk mezzanine storage systems features. You can choose to install them over a working area or an existing shelving space, and they come with an exposed second level. They are ideal for dealing with products that require a lot of storage space, and adding new rooms.

Equipment Components of Mezzanines

The main component of all mezzanine systems is the floor. Along with the floor, mezzanine systems feature the supportive components of columns, beams, fasteners, and joists.

Mezzanine floors (also called ‘decking’) are commonly made of materials like diamond treaded steel, plywood, metal plank, welded bar grates, and various poly texture panels. Usually, mezzanine floors feature base plates that allow them a degree of safe movement.

Columns support the various types of loads that the mezzanine will experience (vertical, horizontal, twisting, etc.). The right size column keeps your mezzanine safe and stable. Standard recommended column tubes are sized 5” by 3/16”. They are configured to support the primary beams in weight distribution.

Beams help brace and strengthen the cross-section of the mezzanines. Primary Beams act as the main support.

Fasteners minimize any obstruction to operations below. Bolts, for example, are a common component of mezzanines. Depending on the application, manufacturers may or may not require that users bolt the floors together, so that they hold safely above the building’s existing work and storage areas. Anchor bolts also make sure that mezzanines have enough seismic connection.

Joists are the fixing points for the decking that spans in the primary beams.

Mezzanine Installation Advantages

There are many reasons for businesses to invest in mezzanines. First, if you wish to grow, you must concern yourself with efficiency, and a large part of that is space efficiency. Mezzanines provide that space efficiency; they are indispensable tools of space management.

In addition, mezzanines save time and money that would otherwise be drained by building expansion and renovation costs related to taxes, construction materials, labor, building permits, etc. They are the perfect solution for those looking to expand their space without altering the square footage of their facility.

Additional Advantages of Mezzanine Installation

- The unused high spaces are maximized without having to expand the floor area of the original building.

- With a mezzanine, the owner can make a distinct separation between multiple spaces while putting the building’s high-rise structure into good use.

- Quick installation without the troubles of acquiring a building permit; hence not many expenses are incurred.

- Feasible to be used as storage areas for heavier equipment or merchandise. Also, it can be customized to any area to meet what the facility needs.

- Since it was installed as an auxiliary to the building, it can be transferred, moved, or even sold when the mezzanine is no longer necessary.

- It costs nearly three times less than expanding the ground floor.

Mezzanine Installation Disadvantages

Before installation, there are a lot of things that need to be considered. The ground floor configuration must be analyzed first in order to determine the right option in choosing what kind of mezzanine to construct. It can either be supported by bothersome posts in busy areas and use significant ground floor space. It can be a mezzanine on beams that is similar to having another floor on a secondary level.

Mezzanine Design and Customization

Materials

Manufacturers always design mezzanines with the focus of safety and efficiency. For this reason, they almost always make mezzanine structural parts from structural steel plates or stainless-steel plates. Mezzanine manufacturers choose steel alloys because they are durable and strong.

In an industrial setting, they usually only go for fiberglass or aluminum flooring components when the mezzanine does not need to support as much weight, as steel plates can be very heavy, not to mention expensive. Fiberglass mezzanine flooring components are also excellent at resisting corrosion.

Generally, manufacturers only consider wooden or composite lumber flooring components for non-industrial mezzanines. Particle board, for example, is a popular choice for non-industrial decks and/or lightweight mezzanine decks to be used in dry areas. (Particle board is a wood composite material composed of several bonded boards.)

Safety Design

Whatever their specific configuration, all mezzanine designs integrate worker safety features. Generally, access stairs are clearly marked with brightly colored or reflective tape and treaded to reduce the risk of slips and falls.

Perimeter railings and handrails reinforce this safety measure. In addition, their modularity allows workers to expand, reduce, relocate, or disassemble them if they encounter any problems or if their requirements change.

Custom Mezzanines

For specialized purposes, mezzanine manufacturers willingly design custom mezzanines with exact requirements, such as a specific shape or floor perforation size. They also offer custom footing, which is footing constructed of metal or concrete that offers a support base for the load-bearing columns of a mezzanine. Manufacturers may also build custom mezzanines featuring a purlin, which is a structural component that provides support to flooring and loads by attaching horizontally to a mezzanine’s primary frames.

In addition, to help with multi-level material storage and retrieval, manufacturers can incorporate furnishings with which workers can reach and safely traverse multiple mezzanine levels. Examples include conveyor and lift systems, stairs, pallet racks, mezzanine racks, shelves/shelving, and/or roof deckings.

Mezzanine manufacturers can also work utilities like water pipes and electrical conduits into mezzanine floors by running them through web bar joists. This is especially common and easy to do on steel and structural mezzanines.

Mezzanine Safety and Compliance Standards

First and foremost, any mezzanines you purchase should always meet OSHA (Occupational Safety and Health Administration) standards. You must also comply with OSHA standards once you begin using your mezzanines. This ensures that your employees are safe and less likely to become injured while working on or around the mezzanines.

In addition, we recommend that you purchase mezzanine products that are certified in compliance with standards from AISC (American Institute of Steel Construction) and IBC (the International Building Code).

Beyond these, other safety and compliance standards your mezzanines should meet are determined by your application and facility location. If you want or require an accessible mezzanine, for example, your mezzanine must be ADA (American with Disabilities Act) compliant. To find out more, talk to your industry leaders before making any purchases.

How to Choose the Right Mezzanine Manufacturer

If you are interested in securing a mezzanine structure, you need to connect with a high-quality mezzanine supplier. To take out some of the stress of your search, we have provided a list of mezzanine manufacturers and suppliers we most trust. You can find this list by scrolling up towards the middle, where it is wedged between the industry information.

The right manufacturer for you will not only offer products in your price range, but will also offer excellent customer service, the standard certifications you need, and the options you need. Before checking out any mezzanine manufacturers, we suggest you write down a list of your specifications, including your deadline, your budget, your delivery preferences, and your post-delivery preferences (installation assistance, parts replacement, etc.). Writing down your specifications will help you focus your search, and help you eliminate any unsuitable manufacturers. Using your list, study the manufacturers we have listed on this page. Pick out three or four in which you see the most potential, then reach out to each of them to discuss your application. Feel free to ask a lot of questions, and don’t forget to reference your specifications list for guidance.

After you have spoken with customer service representatives from each company, compare and contrast your conversations, and pick the right one for you.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services